Machine Manufacturing Workshop

The machine manufacturing workshop of BTS Industries Group is responsible for designing, creating and installing a variety of transfer machines and other equipment needed for mass production of brass parts. Designing and manufacturing all parts, controlling tools, jaws, and machining tools, etc. are done in this workshop. Due to the main nature of the workshop, its continuous coordination with forging, pressing, machining and molding workshops is of great importance. This harmonization of the mass production of complex components and new parts results in maximum precision and minimum time.

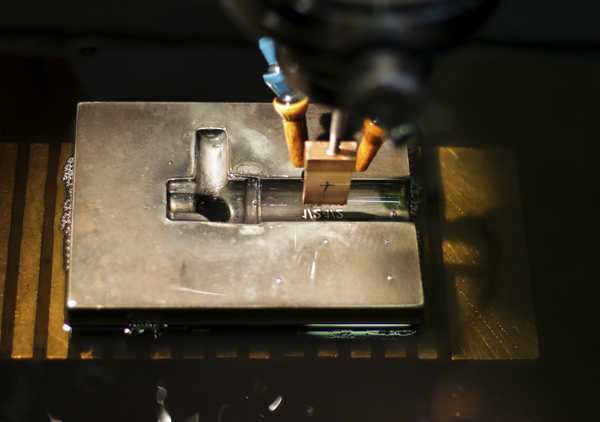

Tool Manufacturing Workshop

Considering the wide range of products manufactured by BTS and the variety of shapes and dimensions of these products, there must be various tools at the transfer workstations for machining these parts. These tools and their holders are designed and created using special tool manufacturing machines in this workshop. Having a specialized space for tool manufacturing which is an integral part in machine manufacturing workshop plays a significant role in producing millions of quality.

Molding and support workshop

Designing and equipping specialized workshops by BTS particularly in regard to transfer machines and designing and manufacturing of required molds is entirely based on national technical capabilities and it is known as one of the most important requisites to meet the needs of the fitting and valve industry. Flexibility in production lines and its diversification along with support and repair of machinery at all time, is the result of this considerable potential.

Forging Workshop

Different steps such as cutting brass bars, preheating, forging, trimming, surface treatment, and removing flashes are performed in this workshop.

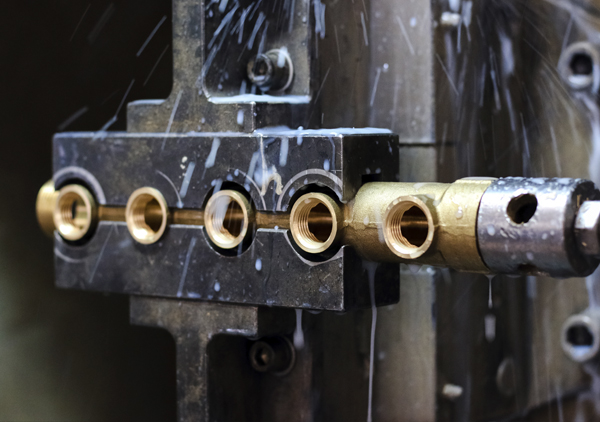

Machining Workshop

Machining workshop is one of the most equipped units in BTS. Manufactured pieces in forging unit enter into this unit to accomplish their manufacturing process. This unit is equipped with the most advanced transfer machines which are exclusively unique. Utilizing these machines allows to perform mechanical processing with highest possible accuracy and speed.

Electroplating Workshop

All the stages of coating process are performed automatically, without human intervention.

Electroplating is performed by copper, nickel, and chrome elements, using advanced facilities available in this unit.

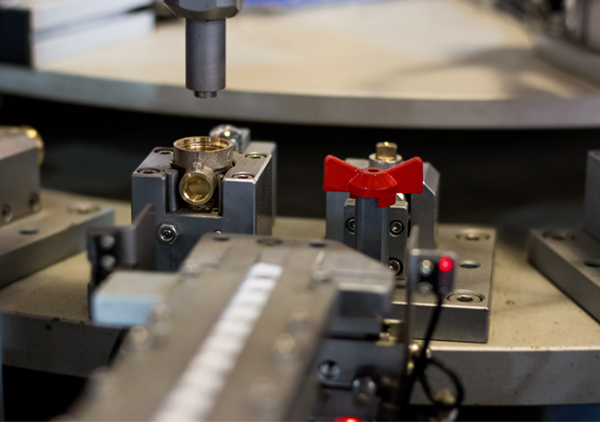

Assembly Workshop

After carefully examining the products in the QC section and confirming their quality, products will enter the assembly line. In this workshop, assembly procedure is done in both automatic and manual ways. In automatic way, machines are fed by separate pieces and then they will be added to the products main body in different steps. In the manual way, this process is carried out by human resources. The assembly of BTS model manifolds and assembled manifolds with valves are also carried out at this workshop and they are examined afterwards. Finally, the product is ready for packaging.

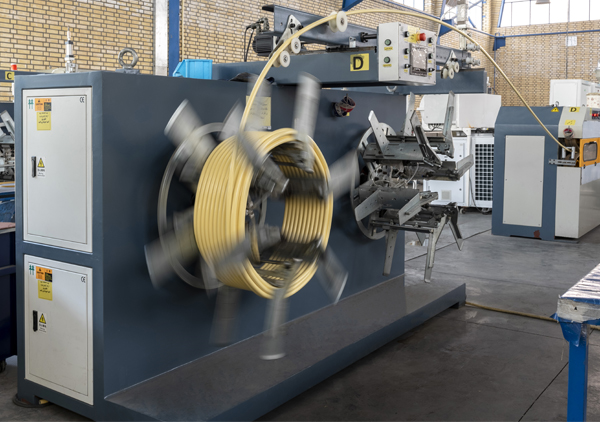

Multi-layer pipe manufacturing workshop

Pipe manufacturing workshop is one of the newest sections in BTS. Pipe manufacturing is highly monitored in this workshop. Every step of production, including selection of high-quality raw materials, device settings and accurate monitoring of production line is done with high sensitivity. This meticulous manufacturing process besides strict quality control over each produced roll of pipe makes the BTS pipes one of the best in the market.